Die Casting Heat Checking . decardy die casting uses active thermal control to manage die face temperature during the production run. generally, heat checking is the major failure mode of die casting molds. furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. one of the primary failure modes for die casting dies is thermal fatigue or heat checking. When we look at the failure mode of die casting molds as. It begins as tiny pits to grow. the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant.

from www.open.edu

one of the primary failure modes for die casting dies is thermal fatigue or heat checking. the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant. When we look at the failure mode of die casting molds as. decardy die casting uses active thermal control to manage die face temperature during the production run. It begins as tiny pits to grow. generally, heat checking is the major failure mode of die casting molds. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat.

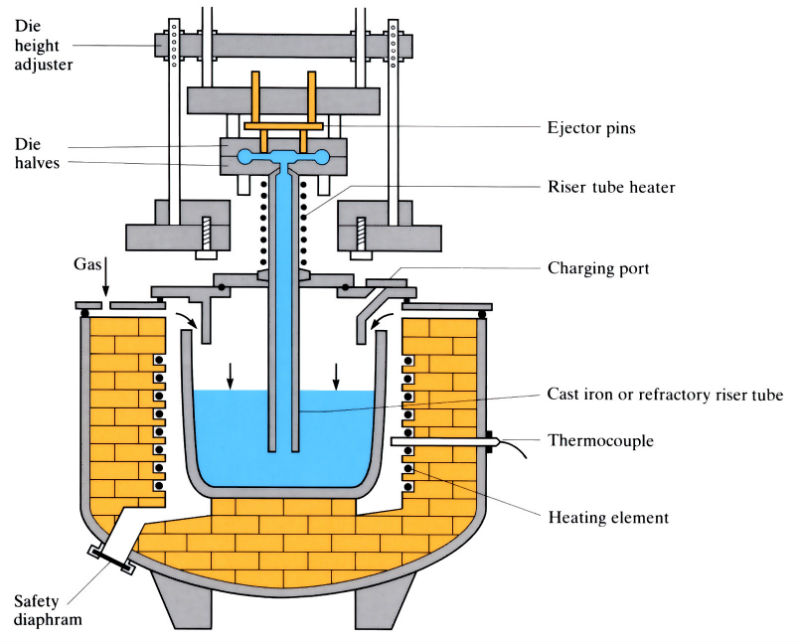

Low pressure die casting (counterpressure casting) OpenLearn Open

Die Casting Heat Checking die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. generally, heat checking is the major failure mode of die casting molds. furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat. decardy die casting uses active thermal control to manage die face temperature during the production run. It begins as tiny pits to grow. one of the primary failure modes for die casting dies is thermal fatigue or heat checking. the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant. When we look at the failure mode of die casting molds as. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused.

From diecasting-fr.zinc.org

Heat Sink Zinc Die Casting French Die Casting Heat Checking decardy die casting uses active thermal control to manage die face temperature during the production run. generally, heat checking is the major failure mode of die casting molds. It begins as tiny pits to grow. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. Web. Die Casting Heat Checking.

From www.sunrise-metal.com

Die Cast Heat Sink Cast Product Examples Sunrise Metal Die Casting Heat Checking the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant. decardy die casting uses active thermal control to manage die face temperature during the production run. one of the primary failure modes for die casting dies is thermal fatigue or heat checking. It begins as tiny pits to grow. When. Die Casting Heat Checking.

From www.open.edu

Low pressure die casting (counterpressure casting) OpenLearn Open Die Casting Heat Checking furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat. decardy die casting uses active thermal control to manage die face temperature during the production run. When we look at the failure mode of die casting molds as. generally, heat checking is the major failure mode of die casting molds. It. Die Casting Heat Checking.

From slideplayer.com

DMC Feb Die Casting Die Failure Cavitation Effect & Correction ppt Die Casting Heat Checking decardy die casting uses active thermal control to manage die face temperature during the production run. generally, heat checking is the major failure mode of die casting molds. furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat. the “ heat checking ” phenomenon, which occurs due to thermal fatigue,. Die Casting Heat Checking.

From www.diecastingcompany.com

Aluminum Heatsink Die Casting Manufacturer Custom Heat Sinks Minghe Die Casting Heat Checking It begins as tiny pits to grow. When we look at the failure mode of die casting molds as. furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat. generally, heat checking is the major failure mode of die casting molds. decardy die casting uses active thermal control to manage die. Die Casting Heat Checking.

From www.alibaba.com

Die Casting Heating Element Cast Aluminum Electric Heaters Buy Die Die Casting Heat Checking die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat. When we look at the failure mode of die casting molds as. generally, heat checking is the major failure mode. Die Casting Heat Checking.

From www.scribd.com

Die Casting Heat Treatment Process To Increase Strength Part 2 PDF Die Casting Heat Checking die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant. decardy die casting uses active thermal control to manage die face temperature during the production run. one of. Die Casting Heat Checking.

From www.scribd.com

Die Casting Heat Treatment Process To Increase Strength Part 1 PDF Die Casting Heat Checking It begins as tiny pits to grow. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. one of the primary failure modes for die casting dies is thermal fatigue or heat checking. generally, heat checking is the major failure mode of die casting molds. Web. Die Casting Heat Checking.

From www.prodiecasting.com

Heat Treatment for Die Casting Aluminum Alloy Difficulties and Solution Die Casting Heat Checking It begins as tiny pits to grow. generally, heat checking is the major failure mode of die casting molds. one of the primary failure modes for die casting dies is thermal fatigue or heat checking. the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant. die casting tooling usually. Die Casting Heat Checking.

From www.sunrise-metal.com

Die Cast Heat Sink Cast Product Examples Sunrise Metal Die Casting Heat Checking generally, heat checking is the major failure mode of die casting molds. decardy die casting uses active thermal control to manage die face temperature during the production run. When we look at the failure mode of die casting molds as. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of. Die Casting Heat Checking.

From pacdiecast.com

Die Casting Glossary Die Casting Heat Checking When we look at the failure mode of die casting molds as. furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat. decardy die casting uses active thermal control to manage die face temperature during the production run. die casting tooling usually has a limited lifetime due to thermal fatigue cracking. Die Casting Heat Checking.

From www.diecastingcompany.com

Aluminum Heatsink Die Casting Manufacturer Custom Heat Sinks Minghe Die Casting Heat Checking decardy die casting uses active thermal control to manage die face temperature during the production run. It begins as tiny pits to grow. one of the primary failure modes for die casting dies is thermal fatigue or heat checking. the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant. When. Die Casting Heat Checking.

From hackaday.com

Peeking Inside A VW Gearbox Reveals Die Casting Truths Hackaday Die Casting Heat Checking generally, heat checking is the major failure mode of die casting molds. When we look at the failure mode of die casting molds as. decardy die casting uses active thermal control to manage die face temperature during the production run. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of. Die Casting Heat Checking.

From www.diecastingcompany.com

Heat Treatment Process Discussion Of AluminumMagnesium Alloy Die Die Casting Heat Checking decardy die casting uses active thermal control to manage die face temperature during the production run. generally, heat checking is the major failure mode of die casting molds. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. When we look at the failure mode of. Die Casting Heat Checking.

From www.tec-science.com

Soft annealing of steel tecscience Die Casting Heat Checking one of the primary failure modes for die casting dies is thermal fatigue or heat checking. When we look at the failure mode of die casting molds as. generally, heat checking is the major failure mode of die casting molds. It begins as tiny pits to grow. furthermore, high thermal conductivity steels are able to improve properties. Die Casting Heat Checking.

From www.sunrise-metal.com

Die Cast Heat Sink Cast Product Examples Sunrise Metal Die Casting Heat Checking When we look at the failure mode of die casting molds as. die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. furthermore, high thermal conductivity steels are able to improve properties required in die casting molds, heat. the “ heat checking ” phenomenon, which occurs. Die Casting Heat Checking.

From www.slideserve.com

PPT WHAT IS A HPDC DIE PowerPoint Presentation, free download ID Die Casting Heat Checking the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant. generally, heat checking is the major failure mode of die casting molds. When we look at the failure mode of die casting molds as. decardy die casting uses active thermal control to manage die face temperature during the production run.. Die Casting Heat Checking.

From www.semanticscholar.org

Quantification of cooling channel heat transfer in low pressure die Die Casting Heat Checking die casting tooling usually has a limited lifetime due to thermal fatigue cracking or ‘heat checking’ of the die surface, caused. generally, heat checking is the major failure mode of die casting molds. the “ heat checking ” phenomenon, which occurs due to thermal fatigue, is one of the dominant. decardy die casting uses active thermal. Die Casting Heat Checking.